This post is in response the Cracked-it challenge posted

The challenge was to create:

A wireless alarm system that alerted her when one of her residential dementia patients gets out of bed during the night and wanders around, potentialy hurting themselves

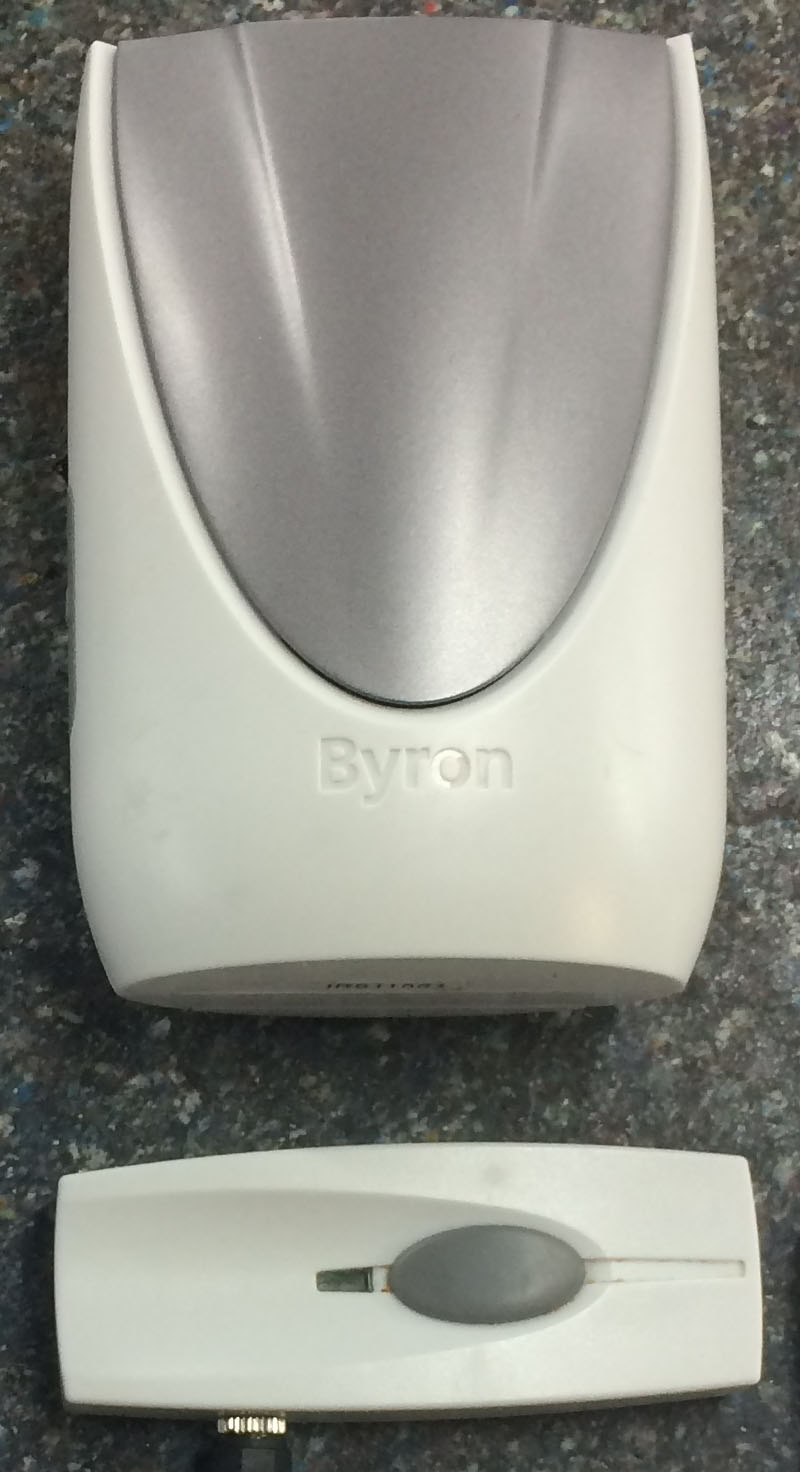

The existing product currently being used in the care home is the AidAlert shown below:

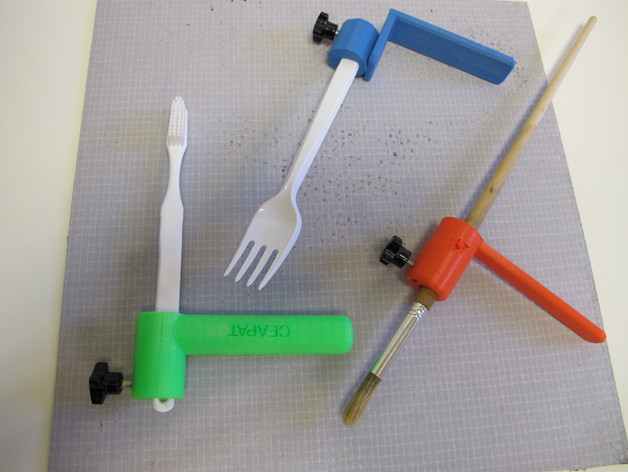

Instead of designing and manufacturing a new product we decided to try and adapt the existing one, historically we have worked with wireless doorbells, utilizing their wireless system for other purposes, our idea was to do the same with this project.

Step One – Existing product analysis and reverse engineering

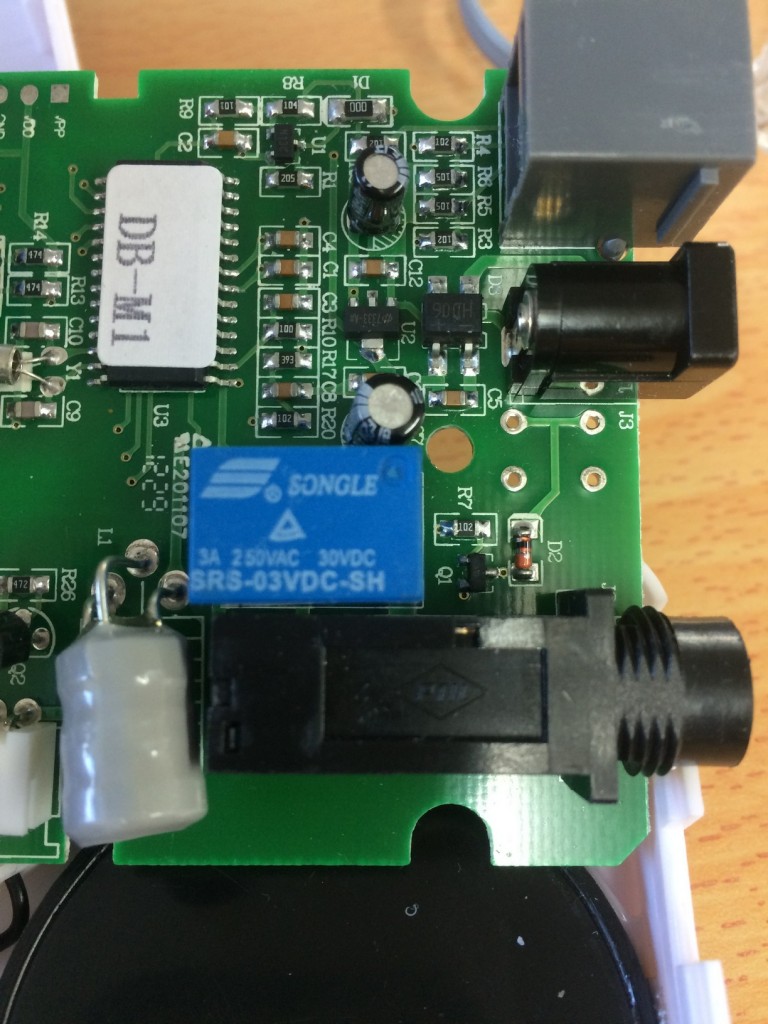

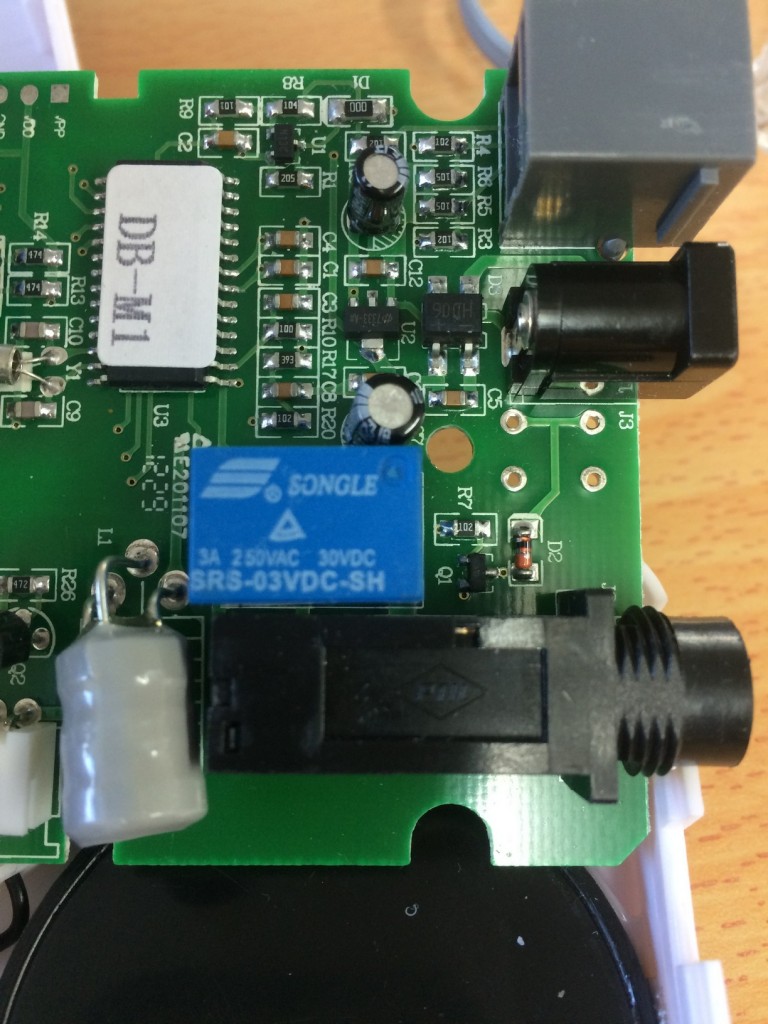

In order to use the existing product as a starting point for our new system we needed to first understand exactly how it worked, in order to do this we opened up the alarm box housing the have a look in side.

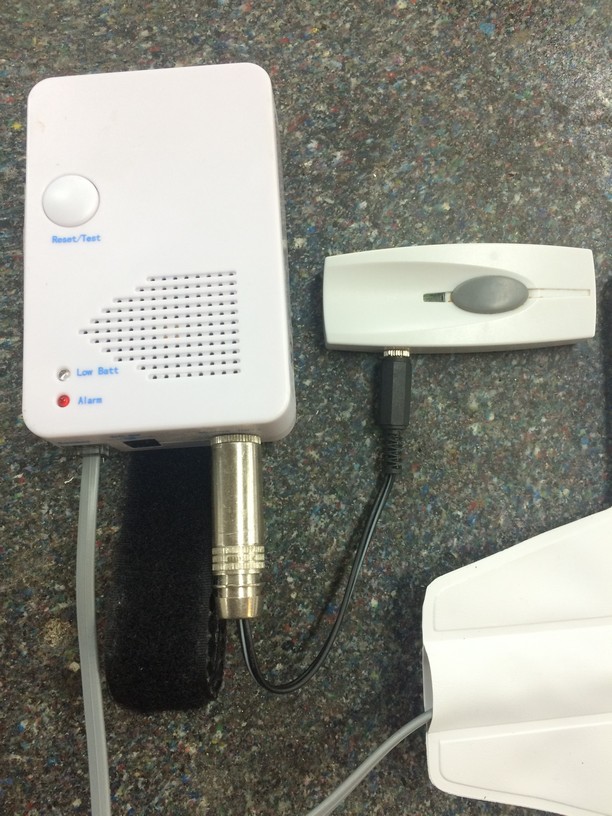

By exploring inside the casing we were able to identify a suitable output that we could use to trigger a wireless doorbell, let me explain; in the image above you can see a blue box, this is an electrical device called a relay, a relay is an electric switch that is turn on and off using a very small current. In this case the relay is connected to the jack plug socket (the black rectangular component shown in the image above).

We noticed that as we pressed on the pressure pad and activated the alarm box, the relay switch would click on. Meaning that when the alarm was activated the jack socket output was turned on, this action in turn could be used to activate a wireless doorbell to alert the nurses.

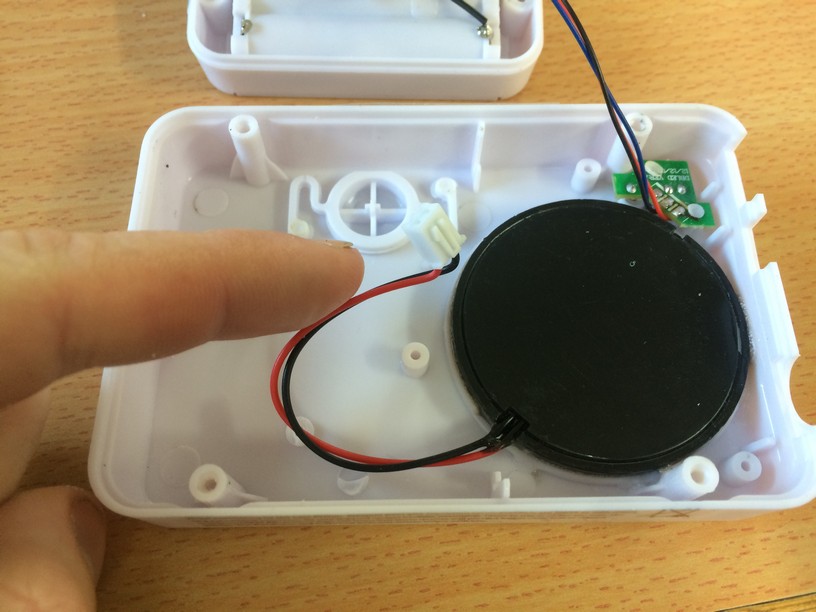

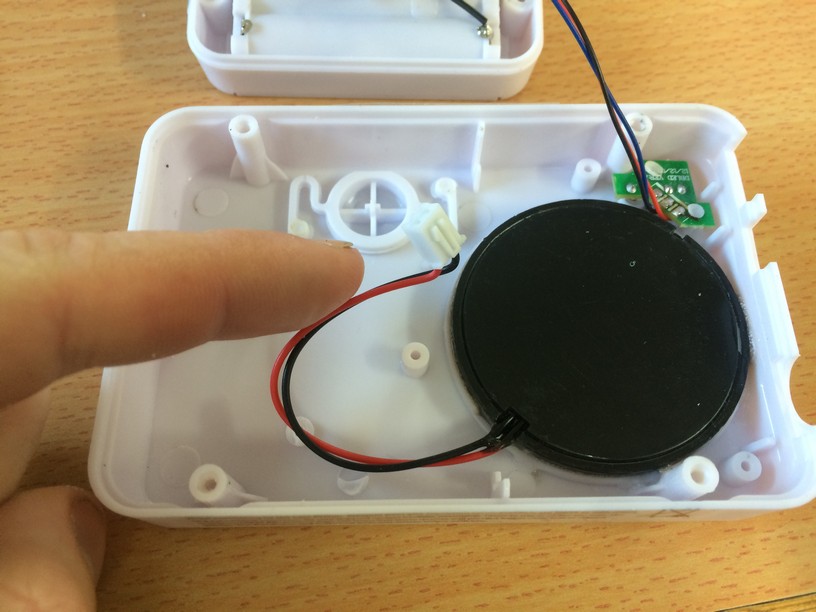

Step Two – Disconnecting the Speaker

Due to the fact that the alarm in the speaker box was scaring the patients, we needed to disconnect the speaker from the PCB, demonstrated in the image above. This allowed us to still use the original alarm box and pressure sensor without the original alarm sound.

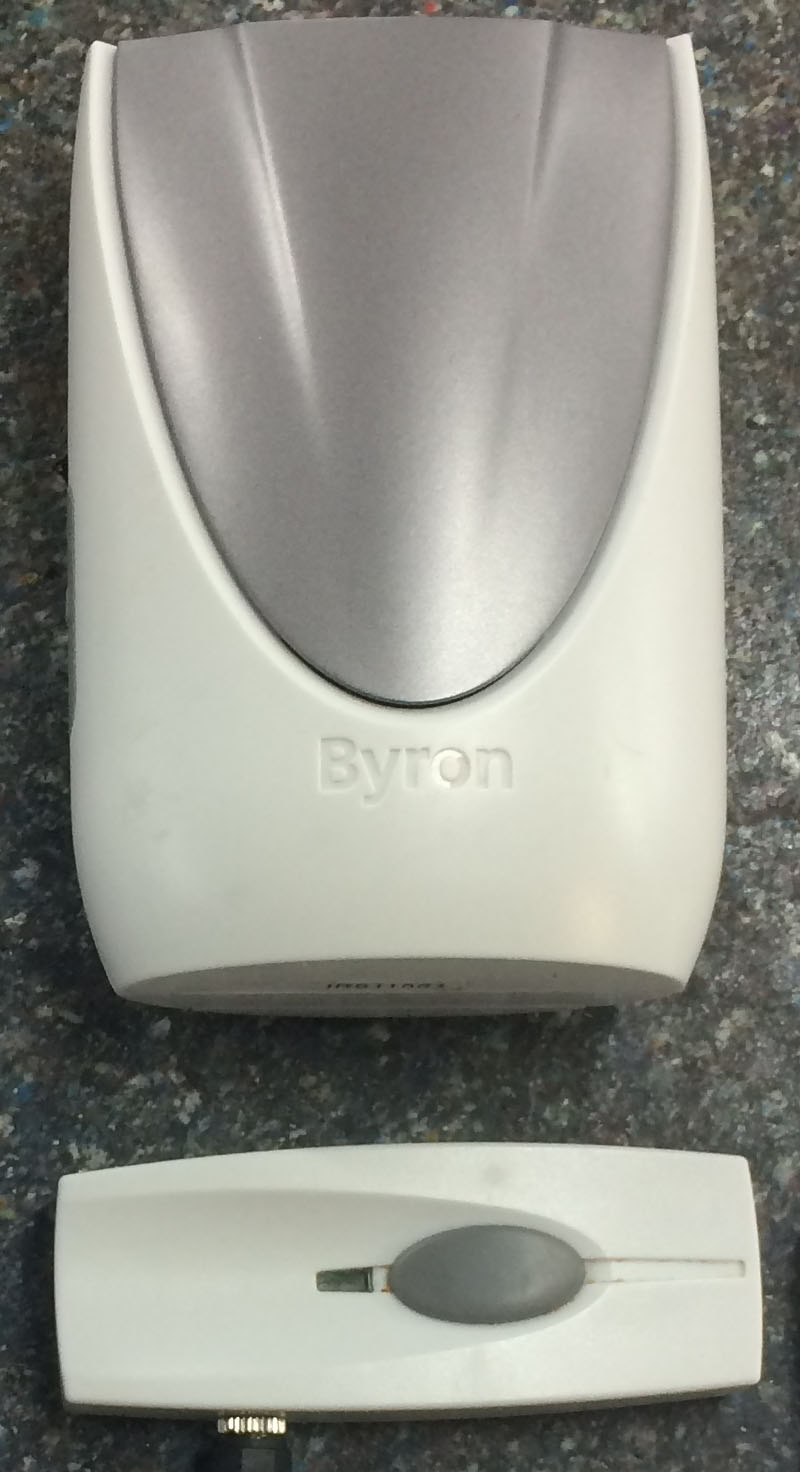

Step Three – The Door Bell

So the plan as it stood was the utilise the spare output on the alarm box and wire it into the doorbell remote shown above, the nurse would then have the speaker with her, or in earshot in the office. Shown below is how we went about wiring the two products together to achieve a working solution.

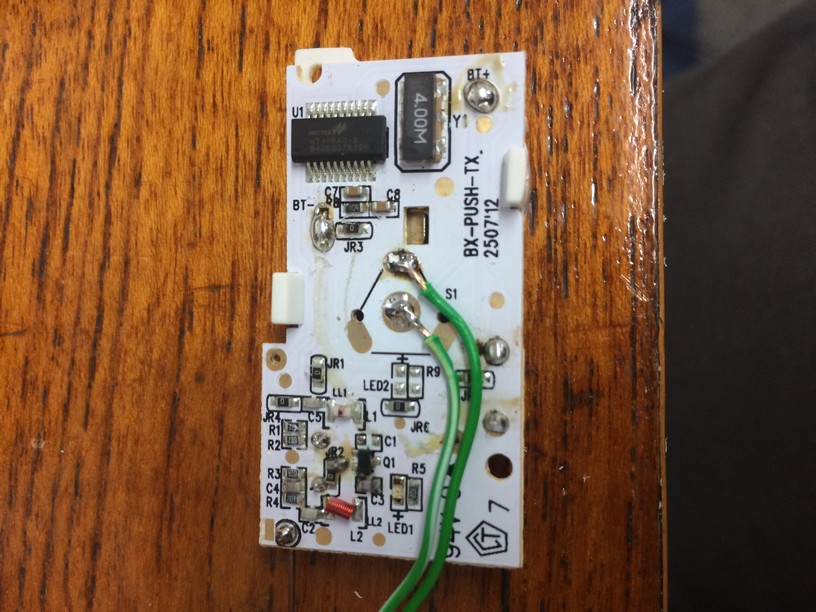

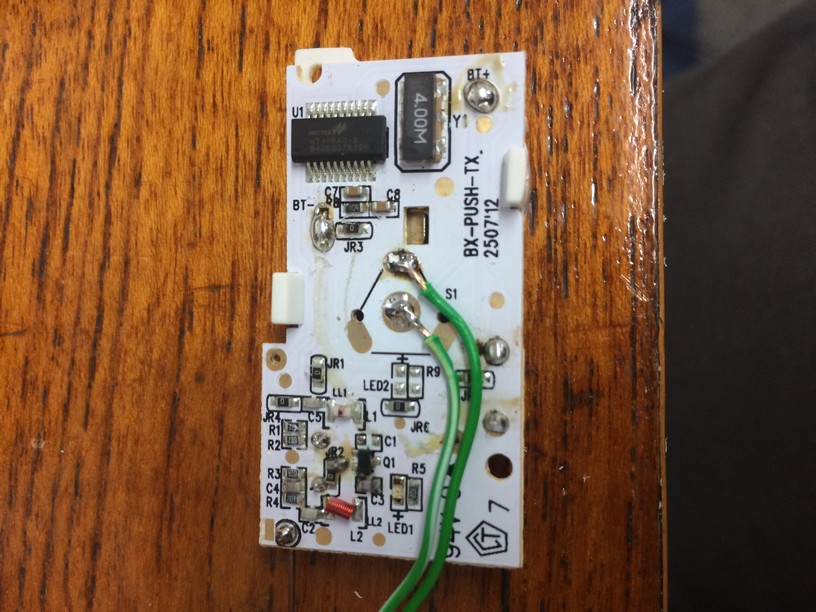

Hacking the Door Bell Remote

In order to use the door bell remote control we needed to find the main switch on the circuit board and ‘short’ it, this meant attaching two wires as show above that allowed us to complete the switch circuit using the output from the alarm box. A female jack plug connection block was then soldered to the end of the two wires and fitted into place inside the doorbell remote control. In order for the connection block to fit, a dremel was used to removed excess material, the image below shows the connection block in place, prior to being wired up.

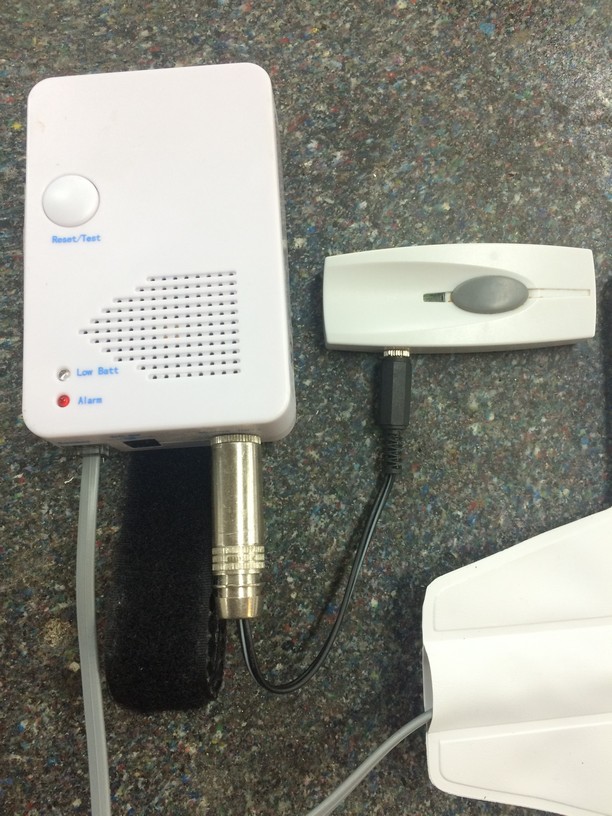

Once the connection block was in place the case on the remote was closed back up and ready for action, the next stage was to make up a cable to connect the remote to the alarm box. This cable consisted of one end having a 3.5mm jack plug and the other having a 1/4 jack plug, shown below:

So the build was complete, when the alarm was triggered via the pressure pad the large jack plug activated the switch on the remote which in turn activated the door bell speaker box.